This prefeasibility study investigated the technical, geographic, regulatory, socioeconomic, and financial viability of capture and geologic storage of CO2 from Nebraska Public Power District’s Gerald Gentleman Station. This Phase I study was part of DOE’s nationwide, four-phase CarbonSAFE Initiative designed to support implementation of commercial-scale CCUS by 2025

As part of a larger effort to investigate CO2 mitigation strategies, the Fort Nelson CCS Feasibility Project investigated the technical and economic feasibility that CO2 from a commercial natural gas-processing facility can be safely and cost-effectively stored in a deep carbonate saline formation. At the time of the research, Spectra Energy’s Fort Nelson natural gas-processing facility was the largest point source of CO2 in the province. Although the site is an exceptional candidate for commercial-scale, long-term geologic storage of CO2, the economics of carbon management in British Columbia did not support the financial case for moving forward with a CCS project at the time of the study.

A small-volume CO2 storage test was completed in a lignite coal seam in Burke County, North Dakota, to determine the fate of CO2 injected into a representative lignite coal seam and to investigate the potential for enhanced coalbed methane (ECBM) production. This effort was the first field project to inject CO2 into a deep, unminable lignite seam in the Williston Basin and successfully used a reservoir saturation tool in conjunction with crosswell seismic to help identify the location of the CO2 plume in the lignite seam.

This feasibility project evaluated potential stacked storage sites in south-central Nebraska and southwest Kansas as a Phase II effort in DOE’s nationwide, multiyear CarbonSAFE initiative designed to support implementation of commercial-scale carbon capture and storage projects by 2025. The project investigated the concept of gathering CO2 from eastern and central NE and transporting it southwest along a hypothetical CO2-source collection corridor into central KS.

A small-volume, short-term CO2 huff ’n’ puff (HnP) test was conducted in an oil well producing from a deep limestone (carbonate) layer in the Williston Basin to evaluate the potential for CO2 storage and EOR at depths greater than 2000 meters. This was the deepest HnP at the time and more than double the preinjection oil production rate was observed over the 4 months the well was monitored following HnP treatment.

Project Tundra is a bold initiative to build the world's largest carbon capture facility in North Dakota. Innovative technologies are being designed to capture 90% of the CO2 produced at the Milton R. Young Station. This capture rate is the equivalent to taking 800,000 gasoline-fueled vehicles off the road. North Dakota-based Minnkota Power Cooperative is leading the project, along with research support from the Energy & Environmental Research Center through DOE's CarbonSAFE initiative.

Learn More About Project Tundra Learn More About North Dakota CarbonSAFE

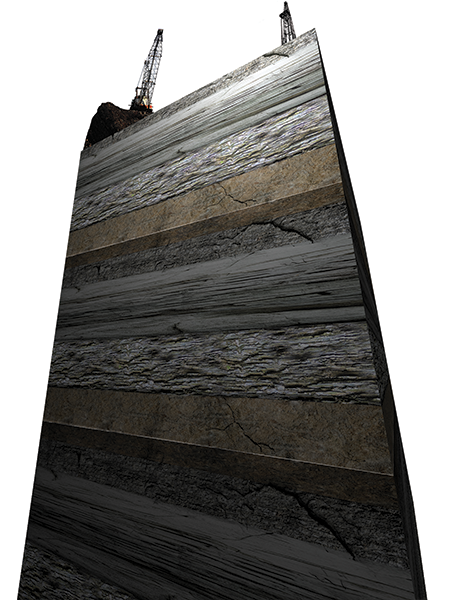

Quest is a fully integrated CCS project—capturing, transporting, injecting, storing, and monitoring CO2. This 98% pure CO2 is transported safely by pipeline to an injection location north of Shell Scotford and stored permanently more than 2 kilometers deep under thick layers of impermeable geologic formations. In less than 5 years, Quest had officially captured and stored more than 5 million metric tons of CO2 deep underground.

Since late 2016, this project has been assessing the technical and economic feasibility of integrating CCS with ethanol production to reduce net CO2 emissions. Recent activities include equipment contracting, public outreach, and submission of the first North Dakota CO2 Storage Facility Permit application, submitted in February 2021.

In the fall of 2014, Boundary Dam Power Station in Estevan, Saskatchewan, became the first generating station in the world to successfully use CCS technology on one of its full-scale units. The facility can capture up to 1 million metric tons of CO2 emissions per year while simultaneously removing sulfur and other pollutants. The captured CO2 either goes to oil fields for EOR or is injected into a 3400-m-deep sandstone formation through the Aquistore Project. In both cases, the CO2 is permanently stored deep underground. After 6 years of operation, the facility had captured more than 3.7 million metric tons of CO2.

This project was undertaken to develop the technical capacity to systematically identify, develop, and apply alternate land use management practices to the Prairie Pothole Region (PPR) ecosystem that will result in GHG reductions. The project demonstrated that restoration of previously farmed wetlands results in the rapid replenishment of soil organic carbon lost to cultivation.

Injection of CO2 for enhanced oil recovery (EOR) began in the Weyburn oil field in 2000 and in the Midale oil field in 2005. In 2020, 2 million metric tons of CO2 was stored at Weyburn, with more than 34 million metric tons of CO2 stored since 2000, mainly sourced from Dakota Gasification Company’s Great Plains Synfuels Plant (GPSP) near Beulah, North Dakota, but with an additional supply of CO2 from SaskPower’s Boundary Dam CCS Facility since 2014. In 2020, approximately 188,000 metric tons of CO2 was injected in the Midale unit. Since 2005, nearly 5 million metric tons of CO2 has been injected. To date, the sale of CO2 from GPSP to Whitecap Resources and Cardinal Energy Ltd. represents the only instances of large quantities of captured CO2 traded across an international border.

The Wyoming CarbonSAFE project is investigating safe, permanent geologic storage of CO2 from Basin Electric Power Cooperative’s coal-based Dry Fork Station in Gillette, Wyoming. Researchers have analyzed geologic samples and used well data to refine geologic computer models to test CO2 injection and storage simulations. Work is addressing all aspects of CO2 sequestration, including initial site characterization, facility design, legal and regulatory issues, providing information about carbon management, and other challenges.

The Zama oil field in northwestern Alberta, Canada, was the site of acid gas injection for the simultaneous purpose of EOR, H2S disposal, and sequestration of CO2. The PCOR Partnership conducted MVA activities at the site, while Apache Canada Ltd. led the injection and hydrocarbon recovery processes.