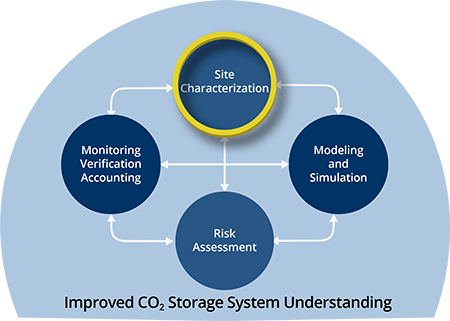

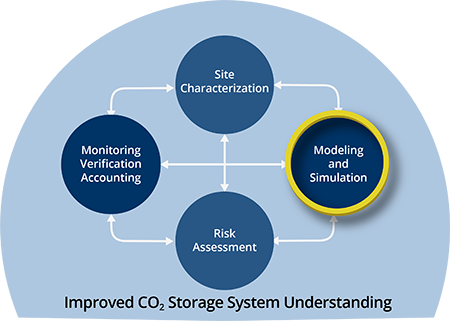

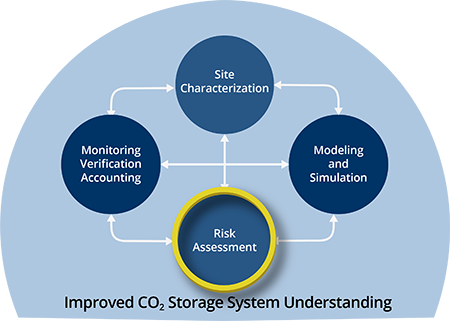

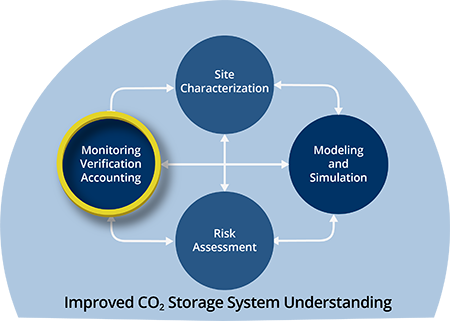

For the purpose of establishing an adaptive management framework, hard lines have been drawn between the technical elements of the adaptive management approach (AMA). However, in practice, the rapid and seamless interaction between the elements can blur these lines.

For example, to aid in the analysis and interpretation of site characterization data, a static geocellular model is often required. While this model development is part of the technical element, modeling and simulation, it is an integral part of the site characterization effort. Likewise, much of the monitoring data collected as part of the monitoring, verification, and accounting (MVA) technical element can be used to inform site characterization. This back-and-forth flow of data and use of models between the technical elements continues throughout the project.

Project Considerations

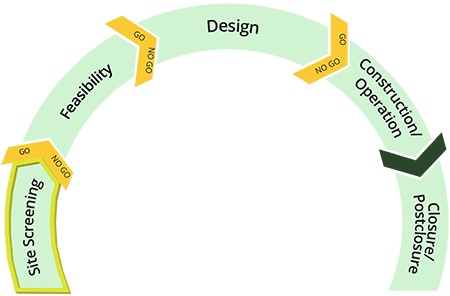

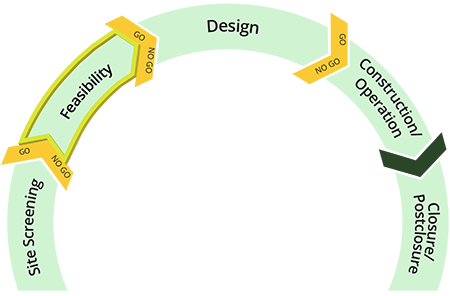

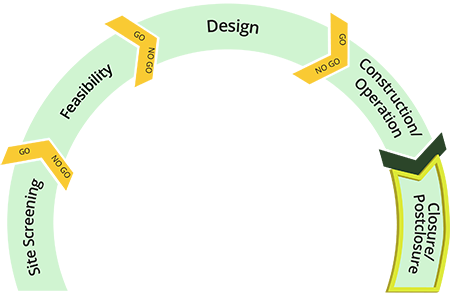

Site Screening

Do candidate storage sites, economically distanced from the source, have the appropriate geologic conditions?

Are there land or subsurface issues, like subsurface proximity to the storage units, that may interfere with storing CO2?

What agency(ies) have regulatory authority over the project, and will regulatory hurdles preclude moving the project forward at the candidate sites?

Feasibility

Are sufficient data available to characterize the storage site or will new data from exploratory fieldwork be required?

What strata combination will define the storage complex? This may consist of a single reservoir and overlying seal or multiple reservoir and seal layers.

How many CO2 injection wells will be necessary to inject the expected quantity of CO2 at the rate it will be delivered to the site? Where should these wells be placed and to what depth?

What surface infrastructure will be necessary to transport and process the CO2 before injection (e.g., size and length of pipeline, CO2 cleanup needs, compression needs, etc.)?

What is the overall footprint of the storage complex, including the area of review (AOR)?

Is it necessary to secure pore space or negotiate access agreements to a portion of the storage site from affected property owners?

What are the applicable state and/or federal regulations and permitting requirements for the construction and operation of the storage system, including MVA? What data are needed to meet these regulatory and permitting requirements? Who is liable for the stored CO2 following the cessation of active CO2 injection?

What environmental risks exist at the site, e.g., potential leakage through legacy wellbores that could impact sensitive environmental receptors?

What project cost estimate, including additional site-characterization activities (e.g., seismic surveys, additional exploration wells, etc.), is required to finalize the facility design or secure required construction and operation permits?

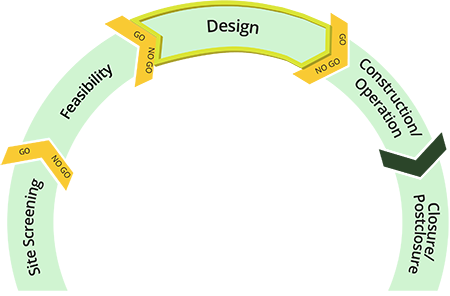

Design

What are the detailed requirements of the necessary surface infrastructure, and what are the costs to deploy and operate the surface infrastructure?

How many CO2 injectors are needed? Where should they be placed, and how must they be constructed?

What MVA-specific elements are necessary to meet the operating and regulatory permitting requirements?

What type of surface and subsurface measurements are needed to implement the MVA program? Where should monitoring instrumentation be placed, and how often should the monitoring data be collected and analyzed?

Are deep monitoring wells required to meet the MVA program requirements? If so, how should they be constructed, and where should they be placed?

What are the costs to deploy and operate the MVA technologies?

What are the major areas of technical risk associated with the storage operations, and can they be managed within acceptable risk limits?

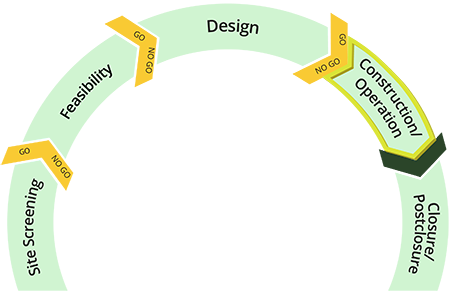

Construction/Operation

Is the injected CO2 securely contained within the storage complex and conforming with model predictions?

Have any unexpected operational issues been observed, e.g., unusual pressure buildup?

Has the project risk profile changed based on field observations and the collected monitoring data?

Closure/Postclosure

What level of information ensures regulatory agencies that the CO2 has been safely stored at closure and will remain in the storage complex during the postclosure period?

Is the risk profile of the site at acceptable levels? What mitigation actions will be enacted if risk levels are exceeded?

How frequently should the site risk profile be updated during the postclosure period?

Cost Considerations

Cost of implementing the project, which will be site-specific and expected to vary considerably as a result of many factors such as scale, scope, current regulatory requirements, and project type.

What is the knowledge base for the prospective project (e.g., Have site characterization activities been completed? Have the requirements of applicable federal, state, and local regulations been defined?).

What is the desired level of certainty required to move from one phase of the project to the next (e.g., Will it be necessary to drill additional characterization wells or collect more seismic data?).

What is the additional infrastructure investment required (e.g., Are there existing pipelines or injection/monitoring wells?).

Improved CO2 Storage System Understanding

Site Characterization

Site characterization includes the acquisition and analysis of data (e.g., installation of wells, collection of seismic data, etc.) to understand the site-specific properties and characteristics of the surface and subsurface environments. Depending on the project phase, several types of data may be collected, including petrophysical, mineralogical, geomechanical, hydrogeological, geochemical, and others (e.g., well logs). Data acquisition occurs throughout the project, although the intensity of the effort and the characterization techniques employed vary with the phases. For example, site screening and early stages of the feasibility phases predominately rely on information from published literature and state regulatory agencies; however, field data collection activities will eventually dominate the efforts of the feasibility phase and into the project design and construction/operation phases. Reduced, but targeted, field efforts during operations are primarily focused on addressing unacceptable risks and/or monitoring anomalies. Site characterization is not typically conducted during the closure/postclosure phase of the project but investigating any unacceptable risks and defining mitigation actions may be required.

Modeling and Simulation

Static geocellular models representing the subsurface, as well as dynamic simulations predicting the effects of injecting and storing CO2, are important for designing a CO2 storage system, assessing the project risks, and designing and interpreting the results of an MVA program. A primary challenge in this stage is balancing the complexity and detail of a geocellular model with the computing power and time needed to generate predictions based on that model. Modeling typically begins early in the development of a project and continues throughout the operation of the site, with precision and complexity increasing over time. For example, preliminary static models with little or no dynamic simulation may adequately meet the needs of the screening phase of the project. However, as the project moves through feasibility toward a final design, running CO2 injection simulations becomes critical in defining the AOR and developing a better understanding of CO2 migration risks and subsurface pressure effects. If field production or injection data exist before the start of CO2 injection, as is often the case for CO2 enhanced oil recovery (EOR) or depleted field sites, then simulation models can be history-matched for improved reservoir performance predictions. Because of the inherent uncertainties in the data that are used to create the static and dynamic models, they should be frequently assessed and, if necessary, revised as operating and MVA data are gathered during the operations phase of the project to allow history matching at regular intervals. Moving into the closure/postclosure phase of a project, the resulting calibrated models should be sufficient to continue supporting the interpretation of MVA data collected.

Risk Assessment

The identification and assessment (qualitative or quantitative) of the potential risks to the success of a CO2 storage project occur early in the development of a project and are refined as more characterization, operational, and monitoring data become available. While a high-level risk assessment may be performed at the site-screening phase using generic lists of risks associated with the geologic storage of CO2, initial risk assessments are usually conducted during the feasibility phase to create a site-specific risk register, which can be updated during subsequent phases of the project based on refined predictions of the system performance. Design-phase risk assessments are especially important since making changes in the storage system configuration and planned operations to eliminate potentially unacceptable risks is still relatively easy.

Conducting risk assessments will continue through the operation and closure/postclosure phases of the project based on data collected through the MVA program. Continuation of these efforts in latter phases of the project is important to demonstrate to the public, federal and state regulators, and other stakeholders that the risk profile of the subsurface storage of CO2 is being continuously monitored and remains at an acceptable level.

Monitoring, Verification, and Accounting

All CO2 storage projects require MVA activities to track the migration of injected CO2 and confirm that the surface and subsurface environments are not negatively impacted by injection activities. MVA data have multiple uses, the primary goal to verify that the injected CO2 and other formation fluids are contained within the target storage complex. In addition, regulatory requirements governing the storage system may require measurement of the total mass of CO2 injected into the subsurface. These monitoring data also provide valuable information to support the other technical elements of the AMA such as the continued refinement of models and simulations and the site-specific risk assessment.

Other than baseline monitoring activities, which may be performed during the feasibility, design, or construction/operation phases of the project, MVA activities are primarily implemented during operations and will continue through closure/postclosure. Technologies including surface, near-surface, and deep-subsurface monitoring techniques will be employed as part of the MVA activities at a CO2 storage site. Many of these techniques, e.g., geophysical logging and seismic surveys, are identical to those used during site characterization; however, the data use is different. During site characterization, data are used to gather new information and/or verify existing data related to the static geologic storage system prior to CO2 injection. In contrast, as part of the MVA program, data are used to monitor the dynamic response of the system during active CO2 injection and document the containment of the CO2 in the storage complex during operation and through the closure/postclosure period.

All information gathered comes directly from the manual "Best Practice for the Commercial Deployment of Carbon Dioxide Geologic Storage: The Adaptive Management Approach."